Complēt™ PKE Formulations

Improve Chemical Resistance, Reduce Carbon Footprint

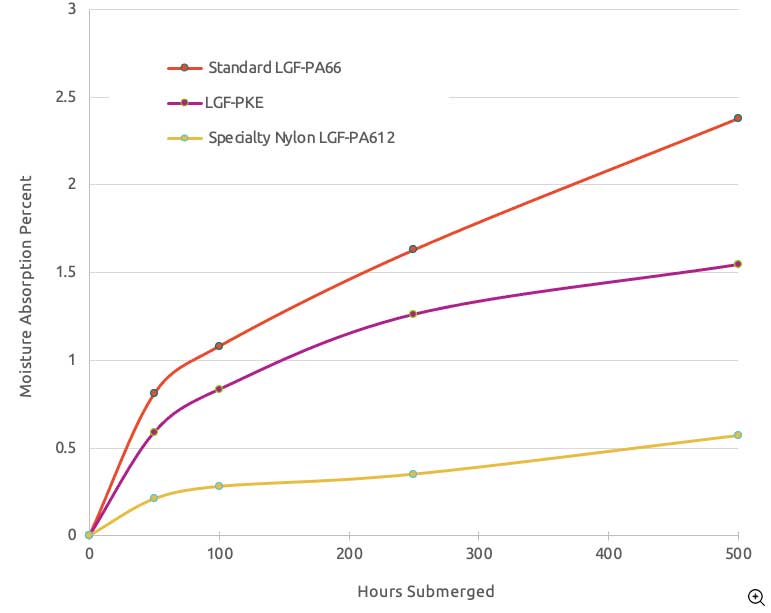

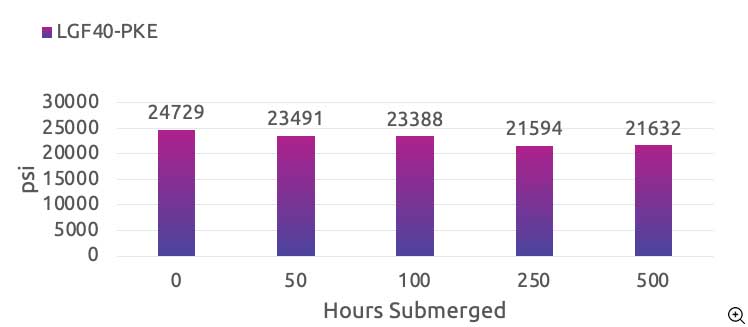

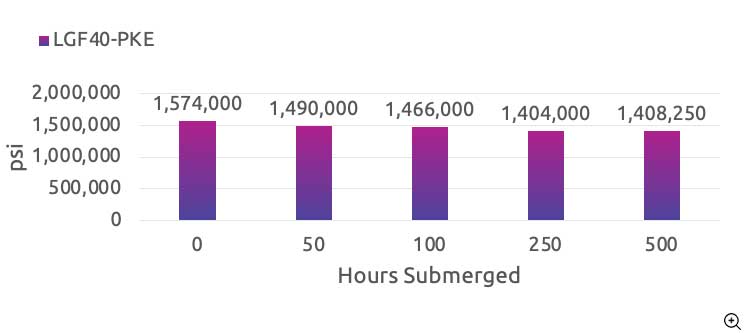

Complēt™ PKE polyketone formulations are long glass fiber reinforced polyketone solutions for structural applications using metal today. These materials are semi-crystalline and deliver excellent chemical resistance, low moisture uptake, and dimensional stability similar to nylon (PA6 and PA66). Polyketone has lower coefficient of friction, similar to acetal, giving it improved wear resistance.

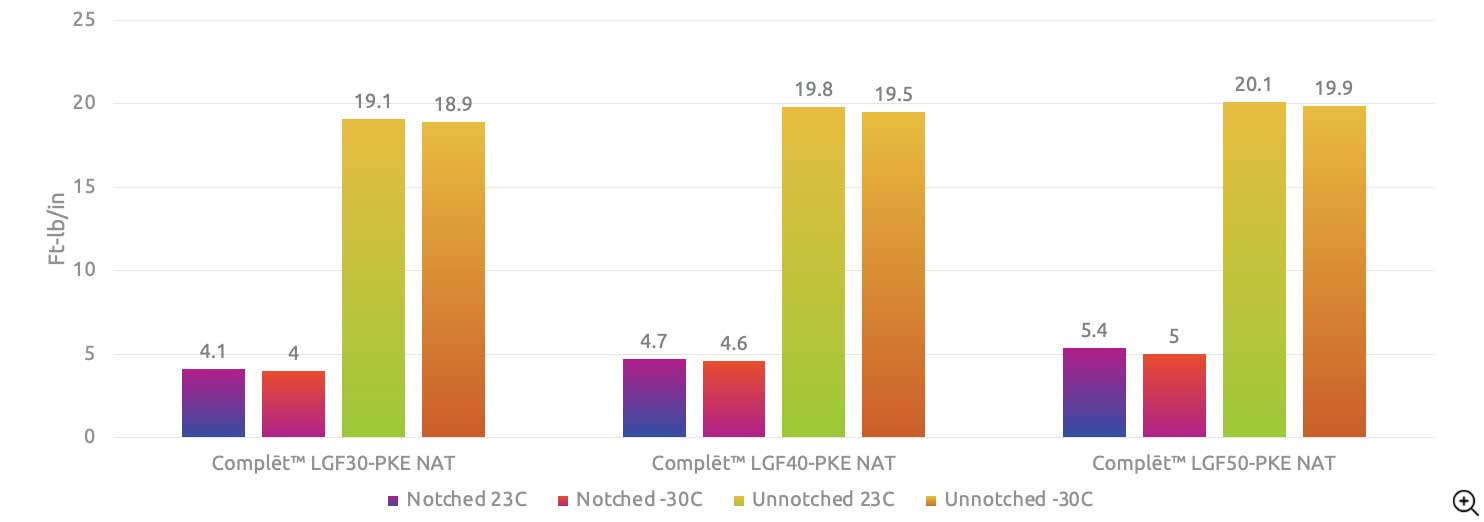

These formulations also offer over 2x higher impact properties than short fiber reinforced, polyketone solutions and, further, maintain impact properties in cold and demanding environments making them ideal candidates for outdoor applications.

Complēt PKE formulations offer a reduced carbon footprint as a result of the base resin, helping to improve sustainability over the end product lifecycle. Manufacturing polyketone results in 61% less carbon dioxide (CO2) than producing PA66 and 46% less than PA6.

These materials are for use in applications in moisture-rich environments or for applications in which chemical resistance or cold impact performance is critical. Market examples include Industrial (pipes, tubing, fluid management), Electrical & Electronics (connectors, battery components), Transportation (under-the-hood fuel/ chemical contact components), and Oil & Gas (fuel pump components, fuel doors).

Benefits

- Chemical resistance

- Maintain high impact performance at low temperatures

- Low moisture uptake

- Dimensional stability comparable to nylon

- Eco-conscious alternative to nylons

- More cost-effective solution than specialty nylon solutions

- Available in non-PFAS* formulations to achieve a UL 94 V-0 flame rating at 1.5 mm

| Technical Property¹ | Test Method | Complēt LGF30-PKE NAT | Complēt LGF40-PKE NAT | Complēt LGF50-PKE NAT |

|---|---|---|---|---|

| Specific Gravity | ASTM D792 | 1.47 | 1.54 | 1.66 |

| Tensile Strength (Yield)(psi) | ASTM D638 | 21,100 | 24,700 | 26,400 |

| Tensile Modulus² (psi) | ASTM D638 | 1,150,000 | 1,570,000 | 2,150,000 |

| Flexural Modulus³ | ASTM D790 | 1,120,000 | 1,480,000 | 2,030,000 |

| Flammability (1.5 mm) (non-PFAS* options available) | UL 94 | V-0 | V-0 | -- |

| ¹Data based on single lot of lab generated samples. Values are not constructed as specifications. ²0.20 in/min ³0.05 in/min | ||||

| *Non-PFAS flame-retardant (FR) grades are manufactured without intentionally added PFAS-based raw materials. They are not available for purchase and are not intended for use in countries outside of North America and South America. | ||||